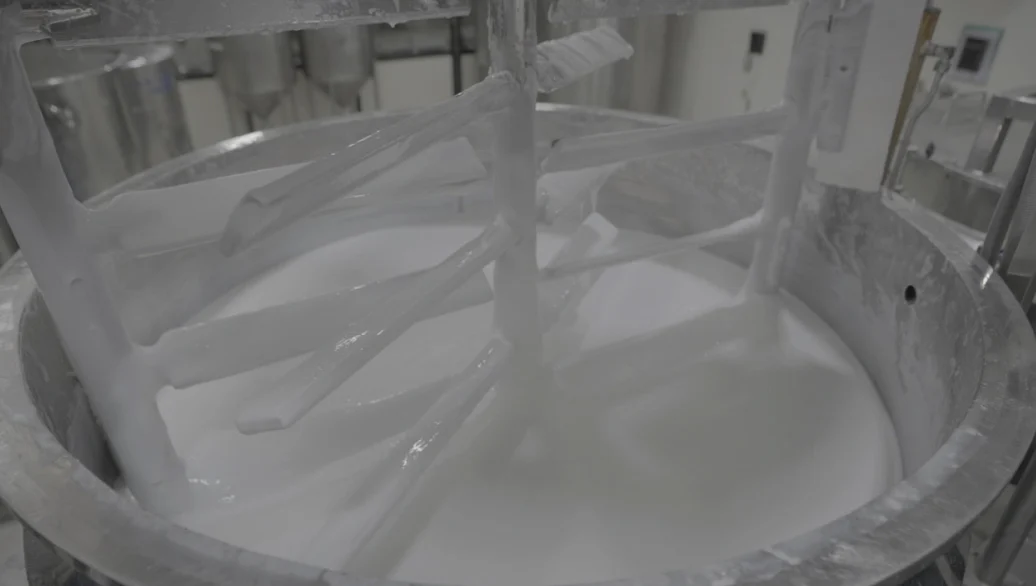

Raw Material Handling & Preparation

- Vessel manufacturing: Capacities ranging from 80KG to 1500KG enable precise formulation development.

- Ointment production: Capabilities exceeding 13.5 tons daily ensure scalability and efficiency.

Tube Filling

- 5 automated lines capable of producing up to 70,000 tubes Daily.

- Compatible with tube sizes ranging from 5gm to 250gm, operating at a speed of 30–50 tubes per minute.

Jar & Bottle Processes

- 4-head automatic filling machines process up to 50,000 jars and bottles daily.

- Handles jar and bottle sizes from 5ml to 1 litre, operating at speeds of 50–120 bottles per minute.

Labeling & Coding

- Labelling Machine: Designed to label round, square, and oval-shaped bottles with precision.

- Batch Coding Machine: Facilitates online batch coding for seamless traceability and compliance.

In-House quality control

- Advanced quality control laboratory ensures rigorous testing at every stage—from raw materials to final products.

- Supports customized formulation testing and stability studies.

Quality Assurance & Regulatory Compliance

- All processes are conducted under FDA-approved standards, certified by ISO22716 Standard, and approved by SGS and other global bodies, guaranteeing product safety and quality with proper documentation.

Global Shipping

- A track record of overcoming challenges, achieving goals, and delivering satisfaction to brands and clients. Also, track-and-trace comprehensive global shipping services streamline logistics and ensure on-time and secure delivery worldwide.